PO Box: 49714, United Arab Emirates.

Email: info@seltecuae.com

- Home

- Products

Roller Chains

Roller chain is made up of two kinds of links: roller links and plate links alternately placed throughout the length of the chain. Rollers should be evenly placed throughout the chain. The advantage of rollers is its ability to rotate when contacting the teeth of the sprocket. Commonly used for power transmission in industrial machinery, bicycles, motorcycles, tractors etc.

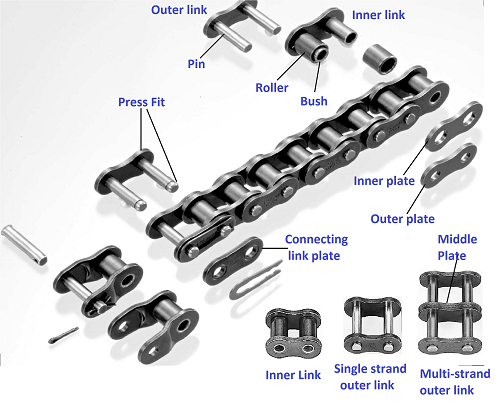

Basic Structure of Roller Chain

Plates :- Bears the tension placed on the chain. Usually this is a repetitive load, but sometimes it is accompanied by shock. The plate must have great static tensile strength and must hold up to the dynamic forces of load and shock.

Pin :- Subjected to shearing and bending forces transmitted by the plate. It also forms a load-bearing part, together with the bush, when the chain flexes during sprocket engagement. Therefore, the pin needs high tensile and shear strength, resistance to bending, and sufficient endurance against shock and wear. Pin are of two types:- Rivet pins and coter pins. According to the pin type, chains are of two types:

- Riveted Chain- Pins have dual staked rivets on both sides.

- Cottered Chain - Pins have dual staked rivets on one side and cotters on the other.

Bush :- The bush is subjected to complex forces from all parts, especially from the repetition of shock loads when the chain engages the sprocket. Therefore, the bush needs extremely high shock resistance. Also, the bush forms a load-bearing part together with the pin, and as such requires great wear resistance.

Roller :- Made of heat treatable steel. The roller is subject to impact load as it strikes the sprocket teeth during chain engagement with the sprocket. The roller changes its point of contact and balance after engagement. It is held between the sprocket teeth and bush, and moves on the tooth face while receiving a compression load. Therefore, it must be resistant to wear and still have strength against shock, fatigue and compression.

Roller Link:- Two bushes are press fit into two inner plates, and rollers are inserted to allow rotation around the outside of the bush. This is the same for single-strand and multi-strand chain.

Link Plates:- Made of properly heat treated alloy steel. They are subject mainly to tensile loads. Shot peening of link plates will cold compact the surface and effectively increase the resistance to fatigue.

Chain Links:- They are of two types- Connecting link and offset links.

- Connecting Link- Used to connect the ends of the chain strand together.

- Offset Link- Used to shorten or lengthen chain by one pitch

- 2 pitch Offset Link- Possess slightly greater load carying capacities than singlr pitch offsets.

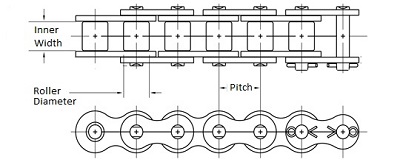

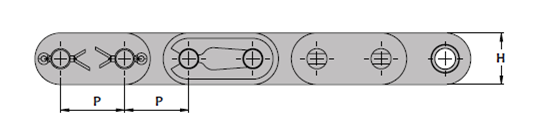

Basic Dimensions of Roller Chain

The three basic dimensions of a Roller chain are pitch, roller diameter, and inner width. A roller chain and sprocket are dimensionally compati ble if these dimensions are identical.

- Pitch is the distance between two pin centers.

-

Inner width is the distance between the innermost sideplates.

-

Roller Diameter is the diameter of the roller.

Types of Roller Chain

Different types of chains are:

- Standard Roller Chain

- Double Pitch Roller Chain

- Lube free- Maintenance free Roller Chain

- Heavy Duty Roller Chain

- Flat Side Bar Roller Chain.

Standard Roller Chain

High Performance Roller Chains are categorized into A series and B series based on the standard they are manufactured.

- High Performance Roller Chains 'A series' - manufactured according to American (ANSI) Standard.

- High Performance Roller Chains 'B series' - manufactured according to British or German (BS) Standard.

Each series is again divided into three:

- Single Roller Chain- Roller chain with one strand.

- Double Roller Chain- Roller chain with two strands.

- Triple Roller Chain- Roller chain with three strands.

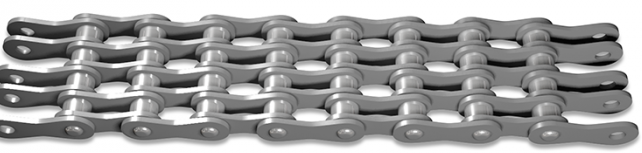

Multiple Strand Chain

A roller chain can be of multiple-strand type. Multiple-strand roller chain consists of two or more single-strand chains placed side-by-side and joined with pins that extend through the entire chain width. It is used to transfer maximum power with the smallest pitch size. For a multiple-strand roller chain, a dash and the number of strands is added to the chain number.

- Examples: 40-2 = standard roller, double strand, 60-3 = standard roller, triple strand.

Double Pitch Roller Chain

All measurements of doble pitch roller chain is similar to standard roller chain except that the pitch is double. It is used in power transmission and conveyers with standard (small) rollers and conveyor series with large (oversized) rollers.

Flat Side Bar Roller Chain

Side bar is straight (flat) rather than contoured. Not available in multiple-strand widths. Used for light to moderate duty material handling conveyor. The straight side bar design also allows unit materials to sit on top of the chains easily conveyor applications.

Lube free- Maintenance free Roller Chain

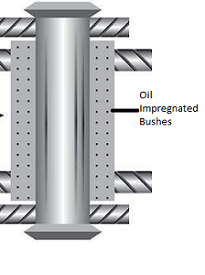

These chains use oil-impregnated, sintered, metal bushings for self-lubrication. The ultimate strength and working load ratings of this series chains are less.

Heavy Duty Roller Chain

Link plates of heavy duty series are one size thicker. They have higher yield strength than standard roller chain. It can withstand greater shock loads. They are available in single or multiple strands.